Polymer for soil stabilization is a hydroactive polyurethane–based system made for strengthening and stabilizing soils and rocks.

Scope of application

Polymer stabilization of soils using polyurethane hydroactive systems is an effective technology that can be applied in a variety of fields:

- Hardening of dry and watered coal-bearing massifs of mining and development faces.

- Improving load-bearing capacity, fixing loose/unstable soils.

- Performing grouting of mountain massifs in order to reduce gas permeation.

- Stiffening rocks in order to strengthen the surrounding massif.

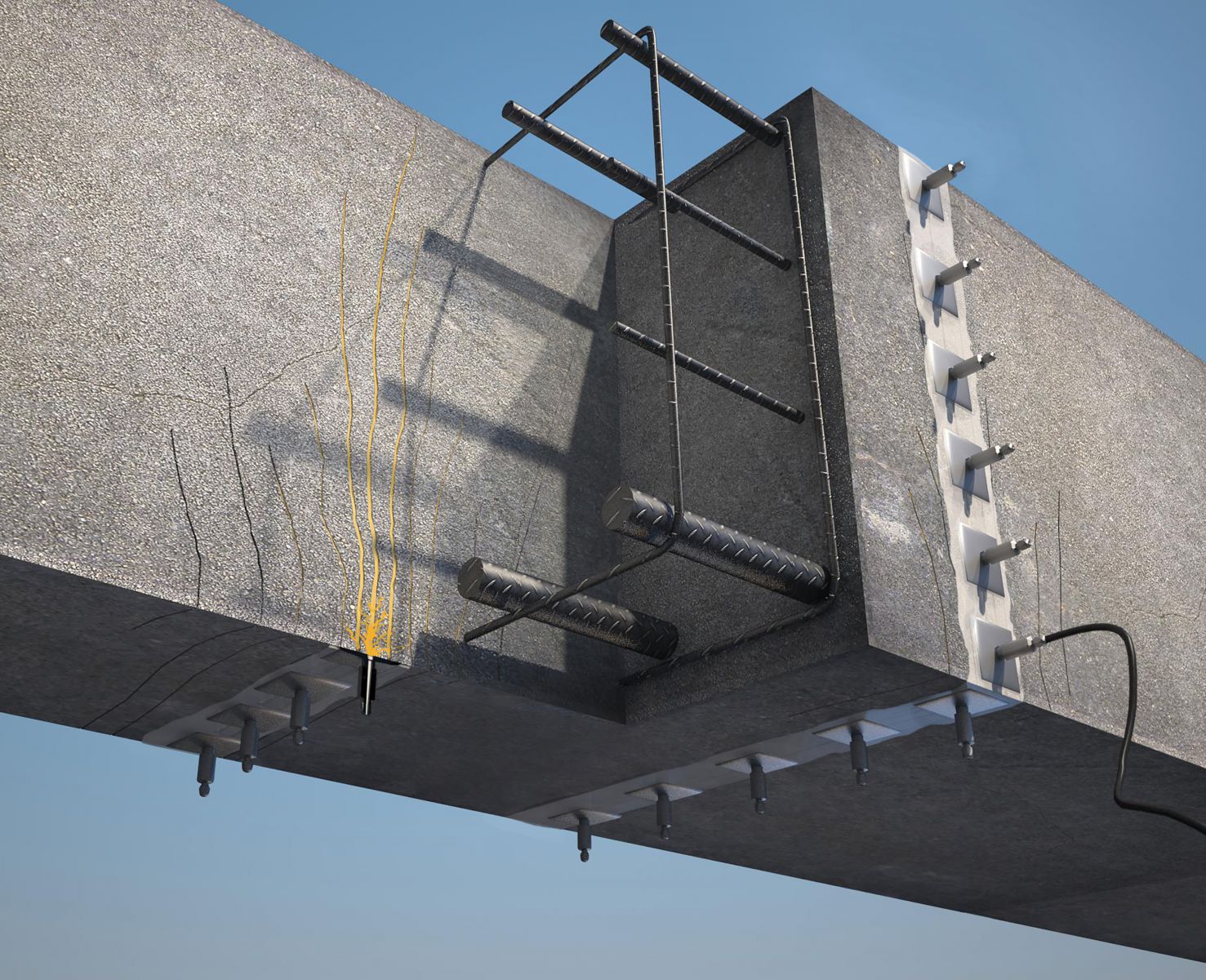

- Works on waterproofing and repairing concrete structures.

- Foundations strengthening.

Injection works are carried out using an injection pump for polyurethane resin. Injection packers are selected taking into account the type of work. Most often builders use self-drilling microinjection drills.

Advantages

Soil stabilization “Gekkon” is a highly effective, reliable, long-life compounds that have many advantages:

- Low viscosity during injection, which ensures deep penetration into the soil.

- The material does not shrink.

- The compounds are absolutely safe for the environment.

- Stable chemical compound guarantees a long service life and mechanical strength.

- Resistance to high water pressure.

- High strength and resistance to deformation.

Conclusion

You can order materials for soil stabilization registered under the trademark “Gekkon” in our company. We have reliable compounds with quality certificates, which are distinguished by practicability and long life time. We sell products directly from the manufacturer, so the price of goods is affordable.

To place an order, please contact our managers at the contact phone numbers listed on the website.